Fiberglass is a fiber-reinforced thermosetting plastic, commonly known as fiberglass. The English abbreviation is FRP. Then the fiberglass membrane shell is a circular pressure vessel with a cover at both ends, and a filter membrane element of different specifications is installed inside it. The fiberglass membrane shell sold on the market is basically produced using spiral winding technology, and only the fiberglass membrane shell produced by Dalian Yuxing Water purification Equipment Co., Ltd. is produced using advanced drawing technology.

First, we introduce the technology of spiral winding: the technology of spiral winding, that is, the fiber beam moving from a horizontal screw nozzle to a rotating core mold. The winding angle is determined by the ratio of the speed of the two. The winding mouth moves in a complex direction along the horizontal direction of the core mold, so that the sand line forms a diamond pattern with a uniform thickness and a constant winding angle everywhere on the core mold. The same direction is adjacent to the sand sheet and does not intersect. The fibers in different directions intersect. In this way, when the fiber is evenly wrapped around the surface of the core mold, two layers of fiber layer are formed in the cylinder section. However, it should be indicated that there will be a certain length of fiber confusion area at both ends of the core mold. When making a pressure vessel such as a fiberglass membrane shell, this section should be removed. The pull winding technology is based on the pull squeeze technology and the ring winding technology is added. Specifically, the fiber sand or its fabric is laid or wound on the core die in different levels, and then pulled out of the mold through a traction device. The whole process is continuous and each layer of fiber sand is only connected without crossing; At the same time, the density and thickness of the product are very uniform, and the dimension accuracy is taken as an example, and the thickness and inner diameter of the product are less than 0.1 mm.

What are the similarities and differences between the two processes described above? First of all, it is a kind of cylindrical pressure vessel as a fiberglass membrane shell. Therefore, the design of its mechanical structure should be designed and calculated according to the relevant technical requirements such as thin shell theory. The fiberglass shell can be divided into three layers, namely inner lining, structural layer and outer protective layer. Each layer has different functions, and the inner lining layer is dense and rich resin layer. The structure layer is a high fiber content bearing layer, which bears the various stresses caused by the load; The outer protective layer provides protection for the aging of the structural layer fiberglass, and at the same time has a decorative effect. As a fiberglass membrane shell, there are basically three kinds of appearance colors, namely white, blue and black, mainly white.

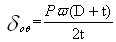

The following formulas can be used for the design and calculation of the body structure of the glass steel film shell:

1, the circular stress caused by internal pressure:

In the formula Δ O θ-cyclic stress;

Pω-Work pressure(or design work pressure)

D-internal diameter of the shell;

T-thickness of the shell wall.

2, caused by internal pressure axial stress:

In the formula Δ X-axial stress;

Pω-Work pressure(or design work pressure)

D-internal diameter of the shell;

T-thickness of the shell wall.

According to the above two formulas, it is not difficult to see that the annular stress of the fiberglass shell shell is twice the axial stress, that is to say, when the spiral winding technology is used for production, as long as the thickness of the annular winding layer is guaranteed. Two times the thickness of the longitudinal laying layer can be. At the same time, in order to ensure the fatigue resistance and 6 times safety factor of the fiberglass shell, the ring stress of the shell should be:[Δ Y] = Δ y/K

In the formula K is the safety factor of the fiberglass shell, usually 6 ~ 10. In the calculation of FRP shell design, we can choose the mechanical strength value of the fiber material, first determine the cyclic allowable stress, and then determine the thickness of the shell according to the diameter of the shell and the design pressure.

From the above simple description, it is easy to see that the adoption of the drawing process technology than the use of spiral winding technology to produce the glass film shell has the following advantages:

The drawing process is continuous production and can process film shells of various lengths as required.

The inner and outer surfaces are smooth surfaces that do not require the cutting or grinding of external surface engines like winding. This not only reduces material consumption, reduces labor intensity, but also reduces environmental pollution.

3, the drawing and winding process can easily ensure the order of fiber arrangement, there is no fiber confusion area where the fibers intersect, so that the performance of the reinforced fiber can be maximized, thus ensuring the stability of the performance of the fiberglass film shell products.

4, the glass film shell produced by the drawing winding process has a good thickness and uniformity of the wall, and the average deviation is not more than 0.1 mm, which can ensure the dimensional accuracy of the porous glass film shell.

5, because the drawing process is more designable and operable, the production of different pressure levels of FRP film shell becomes more simple.

In a word, through the above two kinds of FRP shell production technology simple introduction and comparison, we can see that due to the advanced nature of this new technology, it is bound to FRP shell production and development play a positive role. But what we still need to emphasize here is that regardless of the process of producing a fiberglass membrane shell, it is a layered structure. In other words, the selection of good fiber reinforced materials and good matrix resin materials, to ensure the quality of products is crucial. Because of the characteristics of this layer structure, in order to give full play to the performance of each layer of reinforced fiber, a suitable matrix resin is used to fully infiltrate the fiber, and the bonding strength between the layer and the layer can be high. In order to spread the membrane shell evenly and transfer to each level, it really plays the role of a bridge. Therefore, this is the premise that we must emphasize when discussing the technology of FRP film shell production.

With the continuous development and progress of science and technology, there will certainly be new technologies for the production of membrane shells, and fiberglass materials will also be replaced by other polymer composite materials with better performance. This is what we all hope to see. It is also the inevitable development of the times.

上一篇:已经是第一篇了

下一篇:已经是最后了